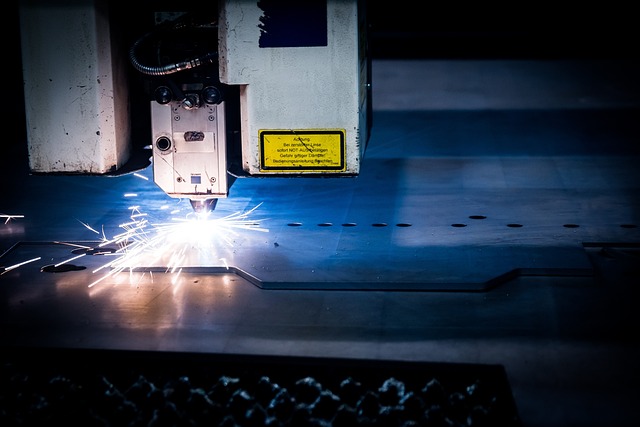

Engraving metal has been a valuable craft for centuries, transforming ordinary surfaces into works of art or precision components. Whether for personal projects, industrial purposes, or creative ventures, selecting the right machine for engraving metal plays a critical role in achieving the desired quality and efficiency. The variety of engraving machines available today caters to different needs, budgets, and skill levels, making it essential to understand what options exist and how they operate.

Understanding the Different Types of Machines for Engraving Metal

When searching for the ideal machine for engraving metal, one quickly discovers that several technologies dominate the market. Traditional mechanical engraving involves a rotary or diamond-tipped tool physically carving into the metal surface. This method offers durability and is widely used for deep, permanent markings. However, it can be labor-intensive and requires significant skill to master.

In contrast, laser engraving machines have revolutionized the field by providing high precision and speed. These machines use focused laser beams to etch detailed designs without physical contact, minimizing wear and tear on the equipment. Laser engraving excels at producing fine details and is ideal for both small-scale custom jobs and larger production runs.

Another category includes CNC (Computer Numerical Control) engraving machines, which combine mechanical tools with computer programming. CNC machines offer automated, repeatable accuracy, making them highly suitable for industrial applications where consistency matters most. The ability to use CAD designs directly makes CNC engraving a versatile choice for complex projects.

Each type of machine for engraving metal has unique strengths, and the choice depends on factors such as material type, project scale, and budget.

Factors to Consider When Selecting a Machine for Engraving Metal

Choosing the right machine requires careful consideration of several elements beyond just the engraving technology. The type of metal you plan to work with is fundamental since some metals respond better to specific engraving methods. For example, softer metals like aluminum or brass can be easily engraved by mechanical or laser machines, while harder metals like stainless steel might demand more powerful laser systems or specialized CNC tools.

The size and complexity of the designs also influence machine choice. If intricate details or fine text are necessary, laser engraving machines typically provide superior results. Meanwhile, CNC machines handle both simple and complex patterns efficiently but may require more setup time and technical knowledge.

Budget constraints are often a deciding factor. Mechanical engraving machines tend to be more affordable upfront but might incur higher maintenance costs. Laser machines offer precision and speed but usually come with higher initial investments. CNC machines vary widely in price depending on their capabilities.

Additional features like software compatibility, ease of use, and available support services should not be overlooked. A machine that integrates well with design software and offers intuitive controls can save significant time and reduce errors.

Maintenance and Longevity of Machines for Engraving Metal

Proper upkeep of engraving machines ensures consistent performance and extends their operational lifespan. Each type demands different maintenance routines. Mechanical engraving machines require regular cleaning of moving parts and periodic sharpening or replacement of engraving tools. Dust and metal debris can interfere with precision, so keeping the workspace clean is essential.

Laser engraving machines generally need less physical maintenance but require careful calibration and occasional lens cleaning. The laser source, such as CO2 or fiber lasers, also has a finite lifespan, and its replacement can be a significant expense. Users should monitor power levels and cooling systems to avoid overheating.

CNC engraving machines benefit from preventive maintenance schedules that include lubrication, alignment checks, and software updates. Since these machines are highly automated, software glitches can impact productivity, making reliable technical support vital.

Investing time in learning proper maintenance procedures not only protects the machine for engraving metal but also guarantees the quality of the finished product remains high over time.

Advancements and Innovations in Machines for Engraving Metal

The industry continues to evolve rapidly with advances in technology, pushing the boundaries of what machines for engraving metal can achieve. Modern laser systems now offer higher speeds and greater precision, allowing for ultra-fine engraving on a wide range of materials. Hybrid machines combining laser and mechanical engraving features have also emerged, providing users with flexibility for various applications.

Software improvements enable better control and creativity, with intuitive interfaces and expanded design capabilities. Integration with automated production lines streamlines workflows, making it easier for businesses to meet demand without sacrificing quality.

Environmentally friendly practices are gaining importance, with machines designed to consume less power and produce minimal waste. As these innovations progress, the future of metal engraving promises greater efficiency, accuracy, and artistic expression.

For more interesting posts visit my blog.